How Much Water is Used to Make Clothes?

Water is an essential part of creating clothes. The fashion industry is a water intensive industry and it is growing exponentially.

As the industry is growing rapidly, the use of water is also increasing rapidly.

The water is used for growing the cotton and dyeing fabrics. A huge amount of water is also used for different stages of garments production.

This is also growing concern for climate change as it is impacted by the use of water. In this industry, the resources are also depleted because of these brands making clothes.

We will try to understand deeply how much water is used to make clothes and the impact of water used on the planet.

This blog post will also explore the water footprint of the clothing and process to reduce the water use.

So How Much Water Is Used To Make Clothes?

In an estimation, Ellen Macarthur suggests that annually almost 93 billion cubic meters of water is used for making clothes worldwide.

This is a critical resource and this critical resource is used for every step of clothing production.

We will deeply drive into the phenomenon of how much water is used for making clothes?

We will also take a look at every step of material production to textile manufacturing to determine how much water is used.

Raw Material Production

The natural fibers, especially cotton production, uses huge amounts of water to produce it.

Estimated that about 10,000 liters of water is used for growing a KG of cotton on an average. One kilogram of cotton fiber can make around 3 to 4 t-shirts.

2700 liters of water is used for producing just one t-shirt. This much water is primarily used for irrigation using the freshwater resources.

It can put a heavy pressure on the local water supplies. So the environment has a significant impact because of the water use.

Also a significant player in this case is cotton. Cotton is only produced in 3% of the arable farm fields.

That’s the reason, central asia, India, midwest America are the prime locations for farming cotton.

These areas are significantly impacted by groundwater depletion because of cotton farming.

Water pollution can use a huge amount of pesticides and chemicals that contribute to water waste.

Synthetic fibers like polyester, nylon are also a significant player of water use. These synthetic fibers are also made from petrochemicals.

This is less water-intensive, but still it requires significant water for processing, dyeing and printing.

Polyester is also known for using 83 liters of water per KG but this is far less than cotton.

Unfortunately it also produces an environmental drawback. Polyester is made from fossil fuels that can lead to microplastic pollution during and after use.

Textile Manufacturing

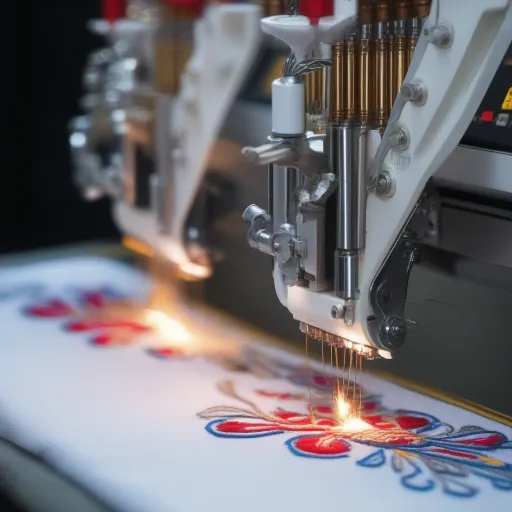

The textile manufacturing process uses a large amount of water, especially during the spinning and weaving sessions.

The water is particularly used for cooling the machinery and washing the clothes.

Water is used in different stages. These stages contribute to the wide footprint in garments.

Water used for raw material manufacturing can consume 200 to 500 liters of water per kilogram.

This also depends on different types of fabric and processing method.

Dyeing and Finishing

Dyeing and finishing can use significant water for this process. The production process can take between 50 to 150 liters of water, just for one kilogram of fabric production.

This can depend on different types of fabric and different types of manufacturing process.

This causes water contamination and it can produce a significant amount of chemicals and toxic waste water.

The consumers and the producers are focusing more on water treatment and adequate manufacturing processes to fight this issue.

In countries like China, India and Bangladesh, these water treatment plants are not used properly. Widespread pollution can reach our lives.

Garment Manufacturing

Once the fabric is dyed and finished for manufacturing, the factory uses the garment then cuts and assembles the garment for final manufacturing.

This can also use a significant amount of water but it is relatively low compared to the other stages.

This water use can be estimated around different phases, including pre-shrinking and shrinking stages.

Sometimes bleaching the garment, ironing and streaming also takes a significant amount of water.

If you consider the global volume, the amount is huge. In particular, denim uses bleaching to strengthen the dye and it takes a lot of water.

Garment Care

Final use of water can be associated with the garment care and maintenance of garments products.

Water is used for washing and drying the product, especially at home after the purchase.

Some consumers use significant amounts of fresh and cold water for washing clothes. A significant amount of water washes synthetic fabrics like polyester and nylon.

These can shed microplastics and the dyeing process requires a huge amount of energy consumption. A water treatment footprint indirectly increases lifespan.

Reducing the Water Footprint of Clothing

Sustainable fashion uses less water for making clothes. The consumers and the producers can take specific steps to reduce the water consumption.

A bit of it can take different stages like sustainable fashion alternatives.

Sustainable fashion alternatives are like using unconventional organic cotton instead of mass produced cotton.

The use of organic cotton reduces the water waste because the organic cotton takes less amount of water for pesticides and fertilizers.

Some of the organic cotton can use irrigation systems. Organic cotton does not produce much of the wastewater.

It only relies on rain water that does not need irrigation. The water also used for hemp or bamboo requires less water.

They can be best for the consumers. The producers can also use recycled materials to reduce the water waste.

It can use recycling and have upcycling procedures to keep the water footprint low. Innovative bands need to be more proactive to use less water.

Technological Innovation

The brands need to be more innovative. They need to be concerned with technological innovation to reduce damage.

The waterless technology can be used for reducing the CO2 emission.

Also water waste is different in different stages. The waterless dyeing technology can use carbon dioxide instead of water for dyeing.

This can have a far less impact than what traditional dyeing is doing.

Efficient Manufacturing Process

Some manufacturers have closed loop water systems. That means they use and reuse the water after treating and recycling.

It can significantly reduce water use and environmental footprint.

Although the technology seems expensive. The consumers can also reduce the water by becoming more concerned about the water use. They can properly dye that fabric with it.

Conscious Consumption

The consumers can play a significant role to reduce the water waste by choosing clothes with sustainable materials.

The consumers can force the producers to produce sustaining clothing. Currently that also has a significant demand in the industry. It can also lead to a lower global carbon emissions.

Supporting The Brands with Sustainable Practice

Consumers can support the brands that produce fabrics ethically and sustainably. That sustainable practices force the fast fashion manufacturers to reduce the water waste. It also reduces the garments used for waterless garments production.

Last words about the water use in clothing industry

The water footprint can be a great issue for the clothing industry. It is growing rapidly. We also need to grow the awareness and innovation in this industry to reduce the clothing waste.

In that way, we can also reduce the water waste. Consumers have the power to make a significant impact in the industry by choosing more sustainable fabric options.

The producers also can take initiatives to reduce the water waste by recycling and treating the wastewater properly.

The government can take initiatives to force market leaders to practice sustainability water treatment.in this way we can reduce the planet’s water scarcity.